Cars are getting more complex by the day. There are hundreds of different parts and systems working in unison to provide the best possible performance, high efficiency, unparalleled safety and comfort, and convenience that were unthinkable just a few years ago. Most of these rely on the car electrics to work. They range from simple switches that open or close windows, more complex parts involved in engine and vehicle management, to the slew of components that bring safer motoring. Connecting all of them to the car battery and fuse boxes is miles of wiring, often neatly arranged in a wiring harness.

What is a Wiring Harness?

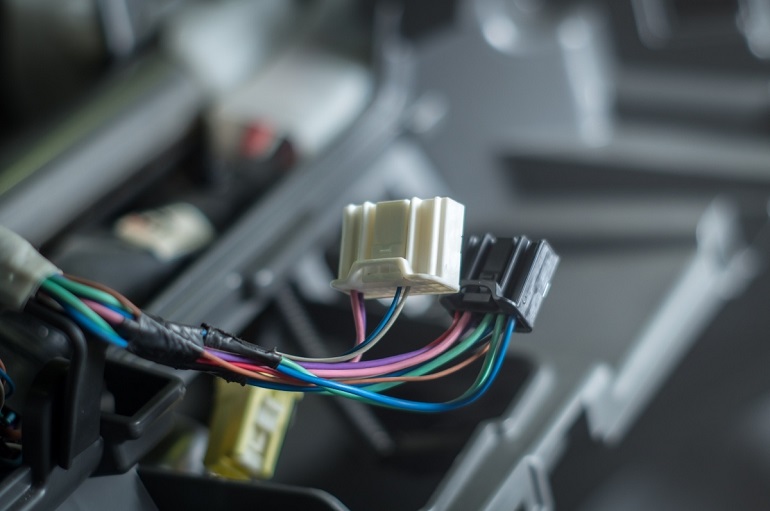

Wiring harnesses are the collection of wires, connections, and terminals, that transmit power and electrical signals to and from different vehicle parts. They aid in the transmission of signals, for instance between different sensors and the car’s computer(s), and provide power to major car components, such as the starter motor, and basic safety elements like the lights.

Why are Wires Bundled into a Wiring Harness

There are several reasons why individual wires aren’t used alone but are found in combination with other wires. The first is that routing wires to hundreds of parts is practically impossible. Cars can have several miles of wiring. And as the type and number of different electrical and electronic components are increasing, this puts significant stress on car design in terms of space, practicality, and time to do so.

Next, is that a single wire won’t last long under the typical adverse effects of heat, vibrations, abrasion, and moisture. By combining separate wires into a car wiring harness and using ample flame-retardant insulation, there’s a lower possibility of electrical faults such as short circuits or electrical fires. This also means that the connected car components work as they should.

Lastly, with multiple wires in a single harness, installation, and repairs are simplified and much faster. This also aids vehicle design, by removing unnecessary clutter and minimising the number of connections. It is easier and less time-consuming to connect multiple wires bundled in a harness to a single connection than separate wires each with their own connection.

Parts of a Wiring Harness

There are several parts that make up a car wiring harness. These include a relay, fuse, fuse block, connectors, and the wires themselves.

Relays

Relays are electrically actuated switches. They use a low input current signal to actuate a much more powerful current. This way they provide a secure connection between the power source, or the vehicle battery, and the component that it powers. Typical examples are glow plug relays in diesel engines, timer relays with timed auto-off in heated rear windows, and those used to turn off the starter motor once it’s completed the task of turning the engine over.

Fuses and Fuse Blocks

Fuses are safety devices designed to melt and interrupt the flow of power once a certain amperage is exceeded. This is how they protect connected components from damage in the event of overvoltage or short circuits. Ideally, each circuit will be protected with its own fuse. Newer cars have blade-type fuses that are considerably more durable than outgoing glass-tube fuses, as they are less prone to damage from vibrations and heat. To make wiring tasks simpler, fuses are collected in fuse blocks, with one in the engine bay, and another in the dashboard or near the steering wheel.

Connectors

Connectors are metal components that connect separate wires in the harness to the fuse, fuse block, switches, or other wires. Aluminium connectors are lost-cost options, but there’s better conductivity with copper and brass connectors. Wires can be connected either by crimping or crimping and soldering. The second method ensures increased conductivity and durability.

Wires

The choice of wires in an automotive wiring harness depends on the application. Here, you need to consider the electrical requirements of the connected vehicle parts and systems. This means wires in the right gauge or thickness to handle the current. Length is also critical, as wires that are too long will lose conductivity due to higher resistance and heat.

Next, have in mind where the wires are used. For instance, those found in the engine bay will be exposed to high heat levels, so choosing wires and harnesses with high-temperature ratings is just common sense. The same goes for wires exposed to moisture (such as switches in window regulators), and areas with pronounced mechanical stresses. The type and quality of the conducting metals and the sheathing are the main factors in this respect.

Avoid aluminium wires as these are often low-grade and need to be in a higher gauge. Go for copper blends or pure copper where possible, despite the higher cost. There are several automotive-grade wires found in car wiring harnesses. Mult-strand primary or GPT wire is resistant to chemicals, oil and high temperatures and used in general-purpose wiring. Motor wire is in finer stands and good for higher current, SXL wire has cross-linked insulation making it ideal for racing applications and where heat and abrasions can be an issue, battery cables are used with batteries, and low-voltage speaker wire for audio applications.

Choosing the Right Wiring Harness

Wiring harnesses are used when adding accessories, such as driving lights or navigation, when upgrading or rewiring older vehicles, or when rebuilding classic cars. In either case, pay attention to the number of circuits (12, 18, or 24) the harness can connect, the wire gauge, length and conducting material, the type of insulation, and the type of connectors used. Buying is simplified with wiring harnesses compatible with both the vehicle parts and systems they are meant for, as well as your car’s make, model, and manufacturing year.